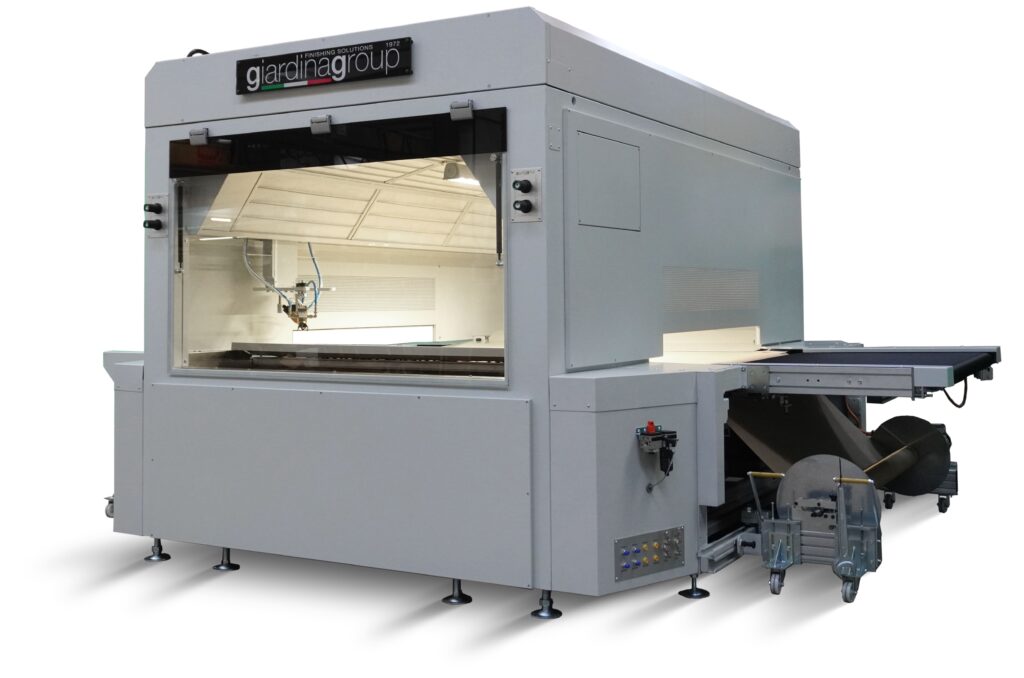

Dualtech 400: reliability and flexibility

The “Dualtech 400″ oscillating sprayer remains one of the most appreciated solutions in the Giardina Group range, a benchmark for reliability, application quality and simplicity of use. The result of over fifty years of experience in spray-coating technologies, the machine is designed to apply stains, primers and topcoats on flat and shaped surfaces, including edges and more complex profiles, while ensuring consistent coating quality even in demanding production cycles.

Its structure, made of carbon-steel profiles and pre-painted panels, ensures durability and stability, while the air-distribution plenum optimizes airflow inside the spray chamber, reducing overspray and keeping the process clean and controlled. The Dualtech 400 can be equipped with the Dualtech spraying system and the Dualfast quick-release system for the guns, allowing flexible management of production cycles and significantly reducing setup times. The gun movement system – up to 4+4 guns – is driven by a brushless motor to ensure precision and repeatability.

The machine’s versatility is reflected in its three available conveyor configurations. The Single Belt (SB) version uses a synthetic belt with Giardina Group’s traditional and reliable self-cleaning doctor-blade system; the Single Belt Paper (SBC) version uses a disposable paper belt to simplify maintenance and speed up colour changes; while the Dual Belt (DB) version combines both systems, allowing operators to choose the most suitable solution for each job. Completing the flexibility of the unit is the dual particulate-filtration system, available in both Dry (dry filtration) and Wet (water-curtain) versions, each featuring a three-stage filtration process.

With a working width of 1,300 millimetres and belts of 1,700 or 2,000 millimetres depending on the configuration, the Dualtech 400 confirms its role as the ideal solution for users seeking the right balance between efficiency, quality and operating costs. A complete and reliable machine, capable of integrating seamlessly into different production environments and delivering consistent results over time.