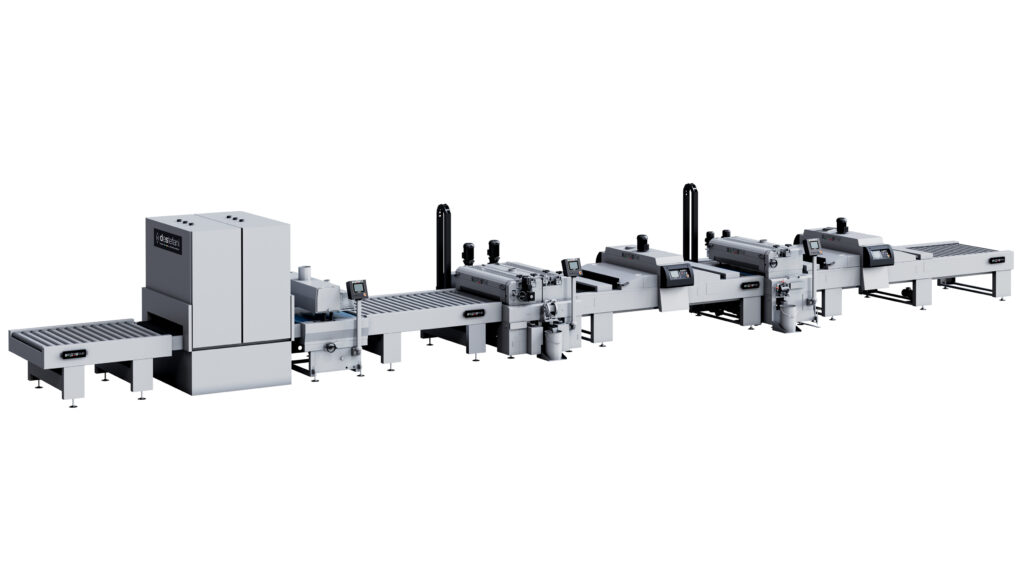

A complete line designed for panels, cabinet doors, and furniture components by Giardina Group

A complete line designed for panels, cabinet doors, and furniture components. With the painting roller line for UV varnishes, Giardina Group confirms its commitment to technological innovation and sustainability. The system integrates all surface finishing stages into a single cycle, ensuring maximum precision, reliability, and significant energy savings. The line consists of a “Movetech BR 2000” loading table, followed by a “Levtech 1350” sander, and then the “Cleantech G02-20” dusting machine. The coating products are applied by the “Rolltech G02-08” roller coater before passing through the “Uvtech GST 1401/2 Plus” UV oven for curing. The piece then undergoes a second roller coating with a “Rolltech G02-05” and a second curing in a second “Uvtech GST 1401/2 Plus” oven. Finally, the piece is discharged through the “Movetech BR 2500” table.

LINE COMPOSITION

“MOVETECH BR 2000”

The “Movetech BR 2000” is a conveyor table with free-rolling rollers coated in solvent-resistant, antistatic, and highly durable PVC. The rollers are mounted with a 140 millimeter pitch and feature safety profiles for increased protection. The minimum transportable piece length is 300 millimeters. Like other solutions in the “MOVETECH” series, it is equipped with an “Atex 3G” electric motor and an IP55 electrical system. The passage width for the pieces is 1,400 millimeters. The table’s drive system is powered by a geared motor with speed adjustable via inverter. The transport plane height is adjustable between 870 and 930 millimeters, and the total table length is 2,000 millimeters.

“LEVTECH 1350”

The “Levtech 1350” is a line automatic sander with a double transverse belt and a fixed working plane at 900 millimeters from the floor. Built with a thick electrowelded carbon steel cage structure, it houses independent belt motors inside the base. The lifting screws are mounted at a wide distance to ensure maximum stability of the steel working plane. The lifting of the plane is motorized, sliding on precision-ground cylindrical columns, with fine adjustment of the working thickness. The efficiency of the “Levtech 1350” is supported by two transverse groups with 5,500 millimeter belts and electronic pads controlled by a 50-sector electronic reading barrier. The conveyor belt, ground, is made of natural rubber. Belt advancement, equipped with automatic centering, is adjustable via inverter from 3 to 18 meters per minute. The digital electronic thickness reader provides a resolution of one tenth of a millimeter. The machine is controlled via a PLC with control keypad and touch screen interface.

“CLEANTECH G02-20”

The “Cleantech” is a panel dusting machine equipped with sectorial rotating brushes and blowers, configurable for each panel surface cleaning operation, including edges, holes, and grooves, on both raw and coated pieces depending on the brush type used. The cleaning group consists of a large-diameter “Tampico” natural fiber mixed with nylon brush and a blower with 16 rotating nozzles that activates automatically when the piece passes. Both cleaning units are equipped with dust extraction hoods. The height of the cleaning group can be adjusted according to panel thickness using a handwheel and monitored with a dial gauge. Machines in the G02 series are modular, allowing different units to be combined to achieve the ideal configuration and meet all panel cleaning requirements before and during coating. It is the perfect solution for brushing, dusting, and blowing operations on one or both faces and the edges of smooth or shaped panels. All G02 series machines can be operated locally or remotely from a central unit.

“MOVETECH BR 2500”

The “Movetech BR 2500” connection table differs from the entrance unit in length, measuring 2,500 millimeters.

“ROLLTECH G02-08”

The “Rolltech G02-08” filler applies UV or water-based primers and fillers of low, medium, or high viscosity to all flat surfaces. The machine consists of a first application group designed to deposit large amounts of product and a second smoothing group with a “reverse” function that pushes the filler into the wood fiber while removing excess product to achieve a perfectly flat surface.

“UVTECH GST 1401/2 PLUS”

The “Uvtech GST 1401/2 Plus” oven is designed to achieve optimal polymerization of coating products on all types of substrates. It features a modular hood housing two irradiating units with high-reflectivity aluminum parabolas and a fan for air expulsion. The “Uv Plus” lamps have a power supply and control system that optimizes energy consumption, allowing continuous voltage adjustment from 20 to 100 percent. This feature provides significant energy savings during downtime and allows adjustment of each lamp’s power to extend its operational life.

“ROLLTECH G02-05”

The “Rolltech G02-05” coater, with three independent speeds, allows application of coating products on all flat surfaces. The machine’s robust structure, built with four support columns and a large rubberized transport roller, allows it to be used in any working condition.

“UVTECH GST 1401/2 PLUS” (Second Unit)

“MOVETECH BR 2500” (Discharge Unit)