Giardina Group back to Zurbuchen

Seventeen years after the first plant, Giardina Group has refurbished the coating line at Zurbuchen Ag in Amlikon, Switzerland, a high-end furniture factory a few kilometers away from Zurich. We must admit that it was the first time in our long career that we travelled to Switzerland to see “live” a furniture industry line made by an Italian company. We were invited by Giardina Group, a leading Italian vendor in the coating business; we were glad to accept and we were really curious, as our idea of “Swiss product” was totally different, and in our industry we expected to come across some business in solid wood or constructions. And instead, it was a different story and we ended up in a wonderful elegant showroom, surrounded by top-quality furniture with excellent design.

To be honest, Stefano Tibè, sales manager at Giardina Group, had prepared us during the journey from Figino Serenza, where the company is based, to Amlikon-Bissegg, very close to Zurich.

“Zurbuchen is a family-owned business managed by the third generation, we provided them with a “high-performance” coating plant back in 2000. Since then, they have grown, developed new experience and identified new needs, but they did not hesitate to come back to us and ask what we could do for them.

And one year ago, in November 2017, the new coating line was commissioned in a company with a strong focus on quality, so strong that they decided to invest a big sum in a plant offering solid guarantees. This plant will not just finish the production of Zurbuchen, but it will be the heart of the company’s subcontracting coating business. Approximately 40 percent of turnover come from high-end office and contract furniture, while 60 percent is generated by sub- contracting operations, namely the production of components, parts and furniture elements for other companies in the region, and of course, all of these parts are also coated. That’s why they chose a line that represents the excellence of our technological portfolio”.

Such need is certainly combined with a passion for “high technology”. We could see this personally as soon as we came to Amlikon: in the Zurbuchen laboratories, we found the world’s best technology, from panel saws to edgebanding, from working centers to presses. And for coating, of course. More than a joiner workshop or a furniture factory, it looks like you are in a luxury restaurant: everything in its place, each tool, even the smallest one, is exactly where it should be; machines seem to have been installed the day before. Tidiness and precision all around… Swiss precision!

Inside the showroom, a summary of all you can find in the factory, where approximately forty people work and generate revenues above eight million Swiss francs: wellcrafted furniture, fla- wless surfaces, a rigorous style with the best functionalities and performance. The company has always made clear choices, such as keeping the entire process under control, from design to assembling, an approach that has paved the way to collaborations with leading customers and architecture studios.

“This is what you want when you choose Zurbuchen”, said Christoph Zurbuchen, co-owner with his two cousins and technical manager of the company. “To achieve uncompromised quality, you must invest in suitable technology: each year we spend half a million francs on average to renew our machinery and ensure the best quality to ourselves and to our customers. For finishing, we have chosen Giardina Group, twenty years ago and again today. The reason is still the same: they can understand our needs and supply a very effective, flexible and smart line. We don’t just have to coat our furniture, we have to do exactly what our customers ask when they turn to us to paint or make components. Some only want us to use specific brands, others prefer water-based coatings, others out- source production operations that require solvent coatings…some even request very peculiar ap- plication cycles. We have selected a Giardina Group line that is highly versatile, built around a five-axis Cartesian robot placed inside a pressurized booth. A “closed-loop line”, that’s how it’s called, where parts are prepared with the necessary basecoats, go through intermediate sanding stages so that each piece arrives to the final coating process in optimal conditions, according to the cycle selected by our customers or ourselves. We process all kinds of materials: solid wood, paper laminates, veneered pieces…”.

Which are the benefits compared to the plant you purchased in 2000?

“Back then, we opted for a dry filtration system, believing it would be more effective for the wide range of processes we had to deal with. For this new plant, instead, they convinced us that the best solution is a water cleaning system and we must admit it is much better for the level of flexibility and quality we need. We have found out that this technology is very sophisticated not only in terms of results, but also because it allows to minimize environmental impact, in full compliance with the very strict regulations applied in Switzerland.

Water is recycled “continuously” and only a small portion of “fresh water” is added into the circuit. The rest if filtered and processed by three pumps that inject chemical products to activate flocculation and the subsequent filtering of coating residues, which can be effectively captured and sent to disposal”.

“Another significant improvement – Zurbuchen added – comes from the self-cleaning conveyor to a disposable paper system: now the belt conveyor of our robot is always perfectly efficient and, at the same time, we have significantly reduced the consumption of solvents for cleaning. Paper is not disposed of, it is sent to a company a few kilometers away to be entirely recycled. Most importantly, we have introduced an air humidification system both in the spraying system and in the vertical oven, which offers enhanced control over the behavior of water-based coatings and, in hot periods, it also effectively supports solvent coatings that are sprayed inside an environment where air is maintained at the right temperature and humidity, so that it does not absorb the liquid portion of the coating product, changing its viscosity and causing finishing problems. Based on this first year of experience, I can tell you that, on the whole, the “yield” of the new plant has increased by at least 30 percent”.

“Working in an environment with 60-65 percent humidity – Stefano Tibè adds – delivers the best result independently of the type of product and the climate conditions, because air does not “subtract” humidity from the coating. As a result, the coating product offers the best performance, with excellent flow properties and wettability, both essential for the best final result. In this plant for Zurbuchen we have put all the knowledge acquired over many years, adapting it to customer needs, production requirements and applicable standards and laws in each country where we install our plants. Don’t forget that Switzerland is an advanced country in these areas, a mature and competent market that de- mands technology with very low environmental impact, highly flexible, capable of offering the best finishing quality and with high customization”.

And what about productivity?

“It’s really good, although what matters most for us is the quality of result rather than the time to achieve it”, Christoph Zurbuchen says. “In each working shift, we finish 400 square meters of surfaces, or 200 if we use polyurethane coatings with longer flash period. Now we can paint “automatically” fireproof doors that we used to paint manually, as we could not load very thick products into the old line. Now we can process elements up to 10 centimeter thickness, and if you consider that these high-quality doors were finished with two basecoats and two topcoats on each face, you can guess the benefits we get from the new Giardina Group line: until one year ago we made no more than ten doors a week, now five times as many!”.

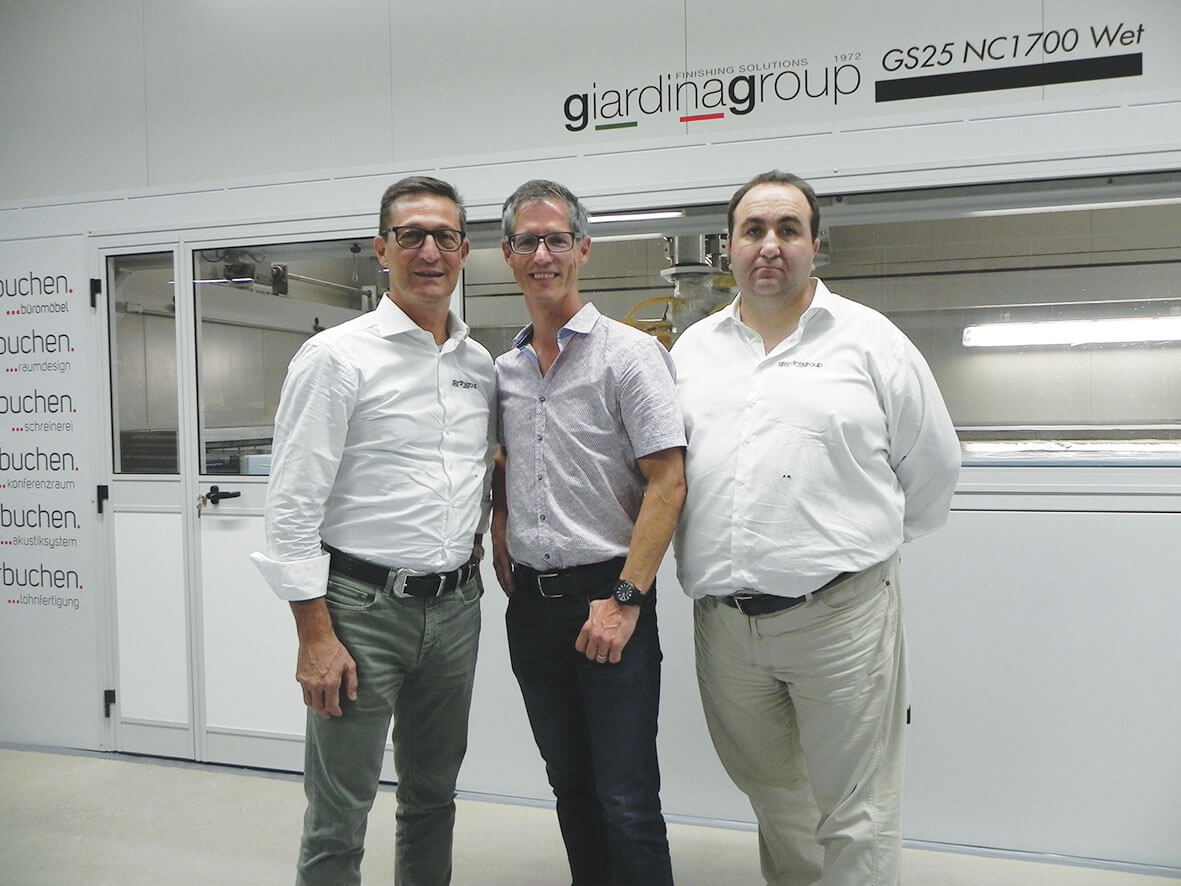

From left: Stefano Tibè, Christoph Zurbuchen and Stefano Mauri.

GIARDINA GROUP LINE FOR ZURBUCHEN

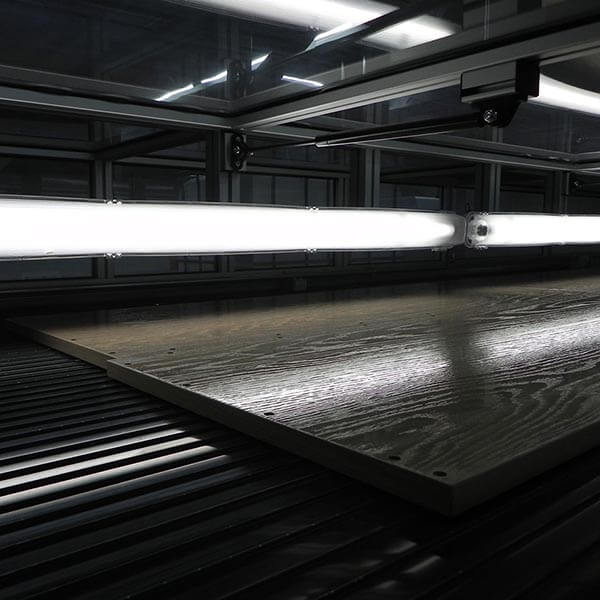

The parts to be finished are placed into a loading conveyor and sent to the machines for accurate cleaning and basecoat application, namely the spraying robot model “Gs25” equipped with a “Combi” model robot head that integrates four different spraying methods. The head features five guns that are handled and operated according to the working program and the scanner that detects part dimensions at the robot infeed.

The subsequent flashing phase is performed in a four-stage vertical oven measuring just below forty square meters, where the pieces are left for two to three hours according to the finishing cycle and the coating products used. The drying process also includes a Uv oven model “Gst 1501/2 3-Dr” and a cooling tunnel. An inline sanding machine processes flat surfaces, while a turning device flips the workpieces that are then sent to a belt conveyor and re-introduced into the line to repeat the same process on the opposite face and obtain the finished piece, perfectly painted on both faces and around the edges, ready to be assembled or packaged.

The plant, monitored by several cameras, is entirely controlled by a “line manager” that supervises each process phase, sending the necessary instructions to each aggregate, to machine the parts according to the production program. The computer controls production in real time and constantly monitors all plant parameters, handling possible maintenance needs or notifying the more or less urgent need for spares, besides offering access to all operating manuals for each aggregate and machine.

So, an “Industry 4.0” solution that provides the production manager – as well as the business owner or the OEM engineers – with all the necessary information for improved management. Also the sanding machine, incorporated into the plant, is enabled or disabled according to the finishing “recipe”. A high-automation plant that can be managed by one operator.

“One of the challenges won by Giardina Group – Stefano Tibè explains – was to design and manufacture such a versatile line within a compact space and just four meter overhead clearance: with specific adjustments to the vertical oven, we managed to offer the same result of a line that should be 300 meter long. It’s a real “tailor made” solution we are very proud of, especially if we consider the very positive feedback from the customer!”.

ZURBECHEN AG

Amlikon (Switzerland)

September 2018

www.zurbuchen.com

Courtesy of Xylon (www.xylon.it)