Lacados y Barnizados Ecolac chooses Giardina Group: a new « Dualtech 400 SBC »

This article, recently published in Madera Sostenible, highlights how the Catalan finishing company Ecolac is strengthening its production capabilities through a customised Giardina Group solution. In a market where subcontractors face increasing product diversity and demanding delivery schedules, Ecolac’s investment in the « Dualtech 400 SBC » demonstrates how compact, flexible and high-performance technologies can significantly enhance quality, efficiency and process control.

Read the original article in spanish!

The Catalan SME has chosen a tailor-made solution to increase its production capacity, ensure application consistency and reduce consumption and waste in an increasingly complex workflow environment.

More and more Spanish subcontracting finishing companies are investing in automated solutions to respond to the growing complexity of their orders. Among them is Lacados y Barnizados Ecolac, a company in the Vallès area that has chosen Giardina Group technology to improve the quality and speed of its processes. The installation of a “Dualtech 400 SBC” with paper transport marks another step forward in the expansion of the Italian manufacturer in the Iberian market.

Lacados y Barnizados Ecolac is a consolidated company in the Vallès production district, specialising in subcontracting work for carpenters, interior design studios, contractors and furniture manufacturers. The company handles a wide variety of pieces and finishes every day, often with tight delivery times: a production model that requires versatility, consistent quality and processes capable of adapting quickly to customer needs.

“We work on very different projects – from private commissions to construction, from retail furnishings to orders for carpenters and designers – and this variety puts us under pressure, both in terms of managing the pieces and meeting delivery times,” says David Hernández, Ecolac’s manager. “With the Dualtech 400 SBC supplied by Giardina Group, we can ensure consistent quality, achieve more uniform finishes and significantly reduce production times. In practice, it allows us to serve customers better, work faster and maintain the standards we want to offer.”

THE TECHNOLOGY

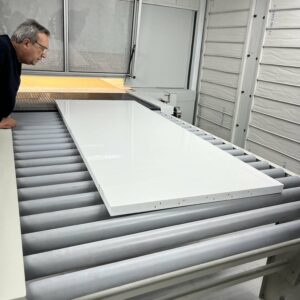

A challenging project for the Italian company, yet completed with excellent results. “This installation required us to integrate the ‘Dualtech 400 SBC’ into a very specific space, where the pieces arrive from a cleaning machine and must be conveyed directly into the drying booth to avoid any risk of contamination after application,” explains Francesc M. Fernández Capilla, Country Sales and Technical Consulting, Giardina Group Spain. “It is a configuration increasingly requested by our SMEs: compact, efficient solutions capable of adapting to real spaces without compromising process quality.”

“We installed a high-quality solution, perfectly adapted to the customer’s needs and capable of handling quick changes of product and workflow within the existing space,” says Miguel Usedo, Giardina Group technician. “We configured the ‘Dualtech 400 SBC’ to unload directly into the drying booth, preserving the application quality and avoiding any risk of contamination. It was a more complex job than a simple in-line installation – Usedo explains – but it was the only truly feasible and safe solution for the customer.”

Added to this is the collaboration with process partners. “Once the machine is installed, the paint supplier – in this case Novalk – comes into play, carrying out tests to adapt parameters and products to the customer’s specifications,” Fernández continues. “Giardina Group knows how to work as a team: our goal is to increase customers’ productivity without forcing them to change supplier, keeping the process under control with standardised chemical parameters.”

Giardina Group solutions are not designed only for large production lines: an important part of the Italian company’s strategy is dedicated to compact and flexible technologies that can also be integrated into small production environments and accompany their growth according to their investment capacity.

And it is precisely this combination of quality and adaptability that convinced Ecolac. The company, always attentive to waste reduction and the efficient management of materials, chose the “Dualtech 400 SBC” also because it ensures more controlled application, reduces product loss and adds value to the finished work. The paper transport system also helps limit cleaning operations, solvent consumption and emissions, improving the overall process.

“Ultimately, we invest to improve customer service without increasing our environmental impact,” concludes David Hernández. “The ‘Dualtech 400 SBC’ allows us to manage our resources better, leaving the most complex tasks to the operators in the booth, while standard pieces move quickly and efficiently through the Giardina Group line.”

giardinagroup.com